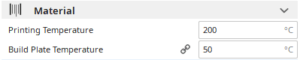

PLA doesn’t actually require heating (but still benefits from it), especially if you use something for bed adhesion, like hairspray. The bed temperature also depends greatly on your material. Remember: only change one setting at a time when calibrating your printer. Ideal temperatures vary between materials (ABS: 220-250 ☌, PETG: 220-245 ☌), but the brand of filament can also make a difference. Most PLA filaments require at least 180 ☌ for smooth extrusion and can stretch up to 220 ☌ before over-extrusion becomes a problem.

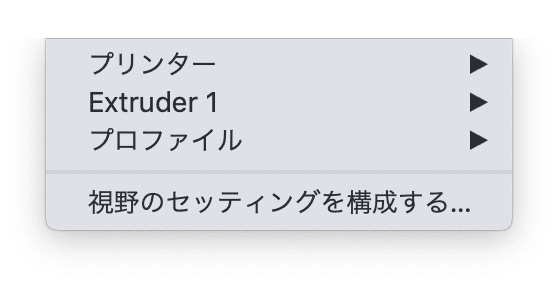

An incorrect temperature setting can cause over or under-extrusion, curling, and blobs or zits. One of the most important settings is temperature. Below is a quick summary of the profile we recommend, with the rest of the article providing a more detailed breakdown of each setting. By default, we’ll build this profile for PLA but also mention settings for ABS and PETG. This is because different types of filaments need different settings to be printed better. Naturally, you’ll have to adapt to individual filaments and resolutions. From here, you’ll have default settings from which to build your perfect profile. Scroll to “Crealit圓D”, expand the section, and select Ender 3. In the preferences box, head for “Add > Add a non-networked printer”. To get started, the stock profile on Cura for the Ender 3 is remarkably good, so definitely load it up as a foundation: Click “Settings > Printer > Manage Printers”. Please note that all these values are based on filaments that we sell (Wanhao, CRON, and Flashforge) as different brands may have different consistencies in their filament. With the help of our friends at All3D we put together this guide for the perfect Cura settings for your Creality Ender 3. Rivaling some of the higher-priced printers in terms of speed, quality, and print volume, we’ve been blown away by this affordable workhorse.

Ultimaker did not specifically describe what exactly they did in these profiles, but they are easily inspectable.The perfect Cura settings for your Ender 3Īre you tired of skipping from blog to blog to find the perfect printing settings for your Creality Ender 3? One of the most popular 3D printers of all time, Creality’s Ender 3 provides an affordable entry point into the world of 3D printing. However, it would be relatively straightforward to replicate Ultimaker’s profile parameters for any other machine. That triggered them to work on optimizing the solid printing approach in Ultimaker Cura, and a way of helping their customers in a very practical manner.įor other companies using Ultimaker Cura as their slicing software, these improvements are not going to automatically appear in version 4.13.1. From that data they determined that many users were printing objects with 100% infill, presumably for making the strongest parts possible. Why did Ultimaker decide to speed up solid 3D print jobs? There’s something users may not realize: Ultimaker provides statistical information back to the company for analysis. The solid print using the Draft Extra Fast profile was 35% faster in my example, and it also used somewhat less material. What’s really interesting is the new Extra Fast 0.30mm profiles, which just rip through these 3D models at enormous speed. However, the normal profiles seem pretty much identical between versions. That is a tremendous advantage for anyone using this combination of software and hardware. Note: new profiles compared against related old profiles Īs you can see, the print times on the solid prints are substantially faster in each case when using version 4.13.1. I prepared a large 3D model of a 100 x 50 x 100 brick and tried various combinations of settings to see how the estimated print time would change on an Ultimaker S5, comparing the same scenario on version 4.12.1.Ĭomparison of Ultimaker Cura estimated print times between v4.12 and v4.13. I wondered how “real” this could be, so I undertook some testing. This means that parts printed at 100% infill will print up to three times faster – perfect for parts meant for engineering environments” The other speed improvement deals with solid 3D prints. In workplaces where you “shouldn’t play with the settings”, this could mean easy access to faster 3D prints. While it was always possible to manually do this, Ultimaker has set up a default profile for their equipment that is now readily available and certified. Compared to the standard 0.15mm layer size, this potentially doubles print speed just considering the number of layers. Trading a coarse surface for a faster print can work in many situations.

This makes sense and is often used by those seeking faster prints at the cost of resolution. This allows you to print up to twice as fast without switching to a larger print core.” “Releasing a brand-new 0.3 layer height option for both the default and draft profiles.

0 kommentar(er)

0 kommentar(er)